In September 1987, a significant moment in environmental history occurred in Montreal, Canada, where the United Nations Environment Programme (UNEP) adopted the Montreal Protocol on Substances that Deplete the Ozone Layer. The adoption of the protocol marked a major breakthrough in global efforts to protect the ozone layer.

With the implementation of the Montreal Protocol and its subsequent revisions, the United States banned the use of HCFC-141b on January 1, 2003, while Europe gradually phased out HCFC-141b and other HCFC substances between 2002 and 2004. Japan implemented the ban a year later than the United States, and other countries and regions also developed schedules to discontinue HCFC-141b products.

In its place, a third-generation high-performance blowing agent called hydrofluorocarbon (HFC) was introduced. The most widely used HFC in the rigid foam industry is 1,1,1,3,3-Pentafluoropropane (HFC-245fa), which was first commercially produced by Honeywell in 2002. 245fa not only meets the environmental requirements for protecting the ozone layer but also satisfies the insulation and flame-retardant performance requirements of the foam industry. Most regions worldwide have completed the transition from HCFC systems to HFC systems, while other regions are in the process of doing so.

On October 10, 2016, another milestone agreement, the Kigali Amendment, was reached following the Paris Agreement. This amendment includes hydrofluorocarbons (HFCs) in its regulatory scope and sets a timetable for gradually reducing HFCs usage by 80% to 85% by 2040. The Kigali Amendment undoubtedly has a significant impact on the Chinese refrigerator industry, which primarily relies on HFC-245fa and cyclopentane as major blowing agents. Meanwhile, the European Union has already introduced regulations limiting the use of HFCs in home appliances and polyurethane foams. These measures have pushed refrigerator manufacturers to choose products with low global warming potential (GWP) in order to remain competitive in the market.

For applications where the use of flammable blowing agents is unsafe, or where the cost of process control is too high, or where performance requirements cannot be met, the two fourth-generation blowing agents have become an ideal choice. These two blowing agents, known as halogenated olefins, contain both fluorine and alkene structures in their main chains, differentiating them from previous HFCs. The presence of a double bond in the main chain of these halogenated olefins gives them a shorter lifespan in the atmosphere and a lower global warming potential.

The alternative path of HFC-245fa as a blowing agent for refrigerators has been widely recognized. Honeywell, as the only company with complete production and technical patents for HFC-245fa, has stated that it will not expand the production capacity of HFC-245fa and will only maintain the current production scale. Xing Yihui, vice dean of Hongbaoli Research Institute, also agrees with this view. He emphasized that the application of HFC-245fa mixed with cyclopentane can significantly improve energy efficiency. In recent years, this method has been popular in the industry and has become the main blowing agent technology path in the refrigerator industry. Although HFC-245fa is restricted in Europe, its use is still allowed in the US market due to Trump’s withdrawal from the Paris Agreement. Besides, HFC-245fa will not be completely eliminated in the short term in China and Southeast Asia, which creates time and space for reducing emissions of HFC-245fa. Therefore, HFC-245fa will still dominate Chinese refrigerator market and maintain a high market share in the next few years.

A spokesperson from Midea believes that for improving energy efficiency of refrigerators without cost pressure, the mixed foaming system of cyclopentane and HFC-245fa is the best technical path. In addition, the actual application effect of the fourth-generation blowing agent Hydrofluoroolefins (HFOs) in refrigerators is not as good as HFC-245fa, and the price is high, making an immediate transition unrealistic. Therefore, HFC-245fa will not immediately exit the market in the short term.

However, despite HFC-245fa still being dominant in Chinese refrigerator market and significantly improving energy efficiency when mixed with cyclopentane, environmental issues remain a significant challenge. As a halogenated hydrocarbon, HFC-245fa still has a higher global warming potential, albeit lower than previous HFCs, and will still have a certain impact on climate.

Therefore, refrigerator manufacturers and industrial research institutions are actively looking for more eco-friendly alternatives. The fourth-generation blowing agent - HFOs - is gaining attention as a potential solution. Compared to HFCs, HFOs have a shorter lifespan in the atmosphere and a lower GWP, making them an attractive option for reducing greenhouse gas emissions.

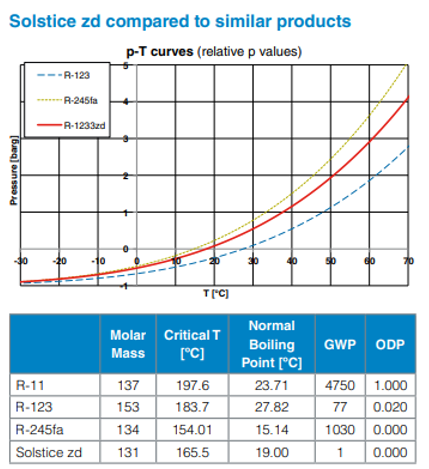

Honeywell’s product specifications reveal that their fourth-generation product Solstice zd (HFO-1233zd) has a GWP value of only 1, which is more than a thousand times lower than its 245fa counterpart.

Data Source: Honeywell

With the increasing global attention to environmental issues, refrigerator manufacturers will have to actively research and invest in new blowing agent technologies to meet stricter environmental regulations and consumer demands. During this transitional period, HFC-245fa will still be an important choice as a blowing agent, but future development trends will inevitably shift towards more eco-friendly solutions.

In summary, the role of HFC-245fa as a blowing agent for refrigerators is undergoing changes. With the strengthening of global environmental awareness and the enhancement of relevant regulations, the refrigerator industry will continually pursue more eco-friendly and efficient blowing agents, thereby driving technological progress and innovation. In the future, we can expect to see more applications of environmentally friendly blowing agents to reduce adverse impacts on the ozone layer and climate.