In the field of 3D printing, the current mainstream material is still polylactic acid (PLA). But due to high elasticity, exceptional shock absorption, and resistance to oils, lubricants and wear, TPU has emerged as one of the most popular materials. Compared to PLA, TPU offers higher flexibility, allowing 3D printed parts to bend or flex more freely during use without easily breaking.

Advantages

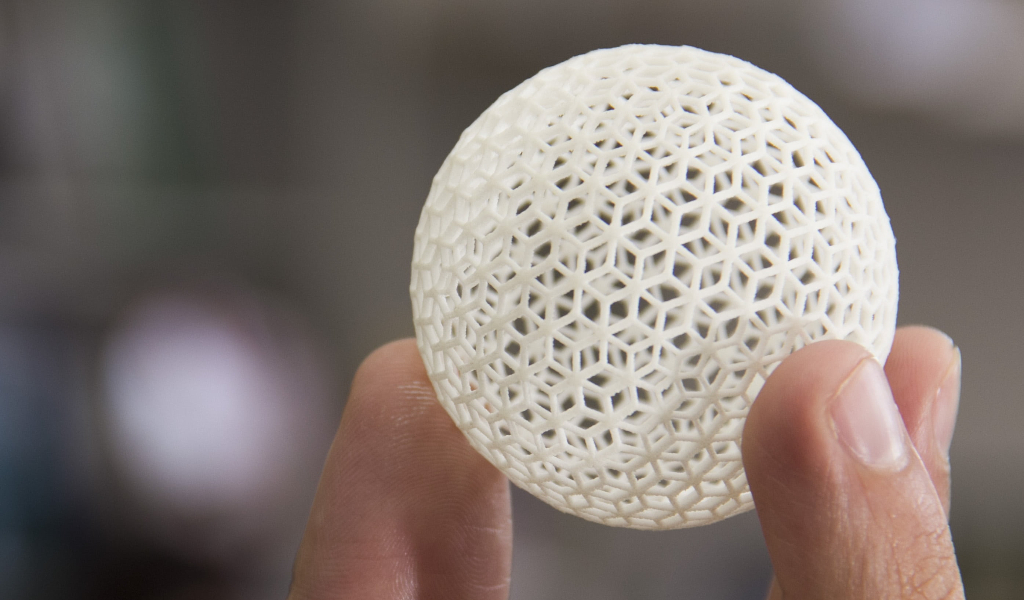

TPU finds wide applications in various fields such as smartphone cases, gaskets, medical devices, and automotive components. As a flexible filament, TPU has continuously expanded its uses in 3D printing due to versatility and durability. Firstly, TPU boasts excellent vibration reduction performance. It can effectively reduce vibration by absorbing and dissipating energy, thus minimizing wear and the impact of external forces on the equipment. Secondly, TPU exhibits good abrasion resistance, with material loss equivalent to only 2% of chloroprene rubber, resulting in an extended lifespan and its suitability as a cushioning material between machine parts. Furthermore, TPU offers a variety of color and hardness options. Unlike carbon fiber products, TPU material provides customers with a broader scope for customization. Its outstanding impact resistance makes TPU suitable for fields like footwear that demand high elasticity, while its high resilience makes it an ideal choice for custom-printed seals, gaskets, and wearable devices.

Major Applications

Automobile

Due to the unique properties of TPU, automakers are major users of TPU. TPU is well-suited for printing lightweight, durable, and customizable automotive parts such as seals, gaskets, and liners. Its inherent flexibility and strength make it an ideal material for manufacturing parts that can withstand severe wear and tear, ultimately helping to enhance the performance and longevity of the final products.

Footwear

TPU are also widely utilized in the footwear industry. With its impressive flexibility and strength, footwear designers use TPU filaments to create innovative designs for improved midsoles. TPU provides better shock absorption, support, and durability, making it an ideal choice for 3D printed shoes, ensuring excellent traction and comfort under various conditions.

Healthcare

The healthcare sector also sees the advantages of TPU. Medical devices must have high flexibility and elasticity, such as medical tubing, wearable biosensors, and custom orthotics. TPU products exhibit excellent sterilization capabilities without compromising performance, making them a suitable choice for products that come into contact with patients.

Challenges

However, there are still some technical challenges when using TPU for printing. To successfully print with TPU, specific printer settings and parameter adjustments are needed to accommodate the characteristics of TPU material. This makes it difficult to easily transfer materials from a conventional PLA 3D printer. Additionally, the loading and extrusion processes of TPU products are relatively complex, requiring careful control of printing speed and temperature to ensure quality and stability. It results in slower forming speeds. Furthermore, during the processing of TPU, other issues may arise such as curling, adhesion, or nozzle blockages, requiring additional attention from operators.

If you are interested in topics such as the current status, market size, and future prospects of polyurethane in 3D printing, and would like to further explore how to realize your ideas, please feel free to contact us. Our team has extensive experience in market research and consulting, alongside innovative solutions. We look forward to assisting you in achieving your goals.

Contactor: Audrey Liu

Cell Number: (+86) 15692117310