Viscosity is one of the important physical properties of polyether polyols. In practical applications, polyols with different viscosities exhibit different performances. Let’s explore this further.

1. Viscosity of Polyether Polyols

Viscosity is a crucial parameter for evaluating the performance of various polyether polyols. In the synthesis of polyols, even with the same raw material ratios, slight differences in the manufacturing process can lead to significant variations in viscosity. Viscosity can help estimate the approximate range of hydroxyl values in conventional analysis. Generally, for polyesters, higher viscosity corresponds to lower hydroxyl values; whereas for polyether polyols, higher viscosity tends to correlate with higher hydroxyl values. The viscosity of polyether polyols typically ranges between 100-500 mPa·s, although the value is influenced by various factors.

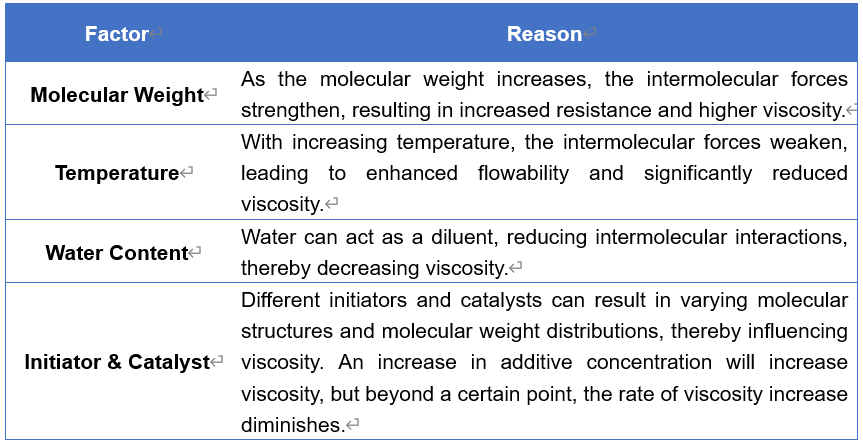

Table 1 Factors Influencing the Viscosity of Polyether Polyols

2. Some Requirements for Polyols Viscosity in Different Applications

Polyurethane Foam: Polyether polyols are one of the main raw materials used in the production of polyurethane foam. The appropriate viscosity can ensure the stability and uniformity of the foam, thereby achieving the desired physical properties.

Adhesives: In the field of adhesives, the viscosity of polyether polyols directly affects the flowability and wettability of the adhesive. Polyether polyols with moderate viscosity can provide good adhesion and water resistance.

Coatings: In the coating industry, the viscosity of polyether polyols has a significant impact on the workability and film-forming properties of coatings. Polyether polyols with moderate viscosity can offer good leveling and adhesion, ensuring the uniformity and aesthetics of the coating.

Elastomers: When preparing polyurethane elastomers, polyether polyols with moderate viscosity are selected to achieve the desired elasticity, strength and wear resistance.

3. Viscosity Control

Viscosity is an important indicator that reflects the degree of polymerization and molecular weight of a product. When formulating polyol blends, it is also crucial to consider the flowability requirements of the blend in the processing. If the viscosity of the polyols is too high, it will decrease the flowability of the blend.

Adjusting Molecular Weight: By changing the type and amount of initiator, as well as the conditions of polymerization (such as temperature, pressure, type and amount of catalyst), the molecular weight of polyether polyols can be controlled, thus changing viscosity.

Temperature Control: During production, temperature can be adjusted in real-time through heating or cooling to control the viscosity of polyether polyols.

Dehydration: Reducing the water content in polyether polyols through dehydration can lower viscosity.

Additives: Suitable diluents or thickeners can be added to adjust the viscosity of polyether polyols according to requirements.

By delving into the viscosity of polyether polyols, it is possible to produce products that meet specific demands across various fields. Viscosity analysis also allows for the prediction of performance variations among different batches of products, thereby guiding production decisions. With advancements in technology, viscosity control will become more precise and efficient, providing robust support for a wider range of applications.