Recently, Xiangyuan Chemical has achieved a key technological breakthrough in the research and development of high-performance polyurethane fiber composite materials. This material can replace traditional metal materials and combines the advantages of light weight, high strength, high wear resistance, temperature resistance, weather resistance, and green low-carbon performance. It represents an inevitable trend in the development of future materials and provides brand-new solutions for structural upgrading in fields such as construction, agriculture, photovoltaic power generation, rail transit and vehicle systems, automobiles, aerospace, and municipal infrastructure.

Technological breakthrough in high-performance polyurethane fiber composite materials

This high-performance composite material uses polyurethane as the matrix (polyurethane component A + polyurethane component B independently developed by Xiangyuan Chemical), with fiber reinforcement, and is produced by continuous pultrusion. It features easy processing, quick effectiveness, optimized structure, excellent performance, and integrated functionality. The composite material process technology developed this time by Xiangyuan Chemical can use various reinforcing fibers such as glass fiber, basalt fiber, and carbon fiber, and flexibly combine them according to product requirements to achieve customized material properties.

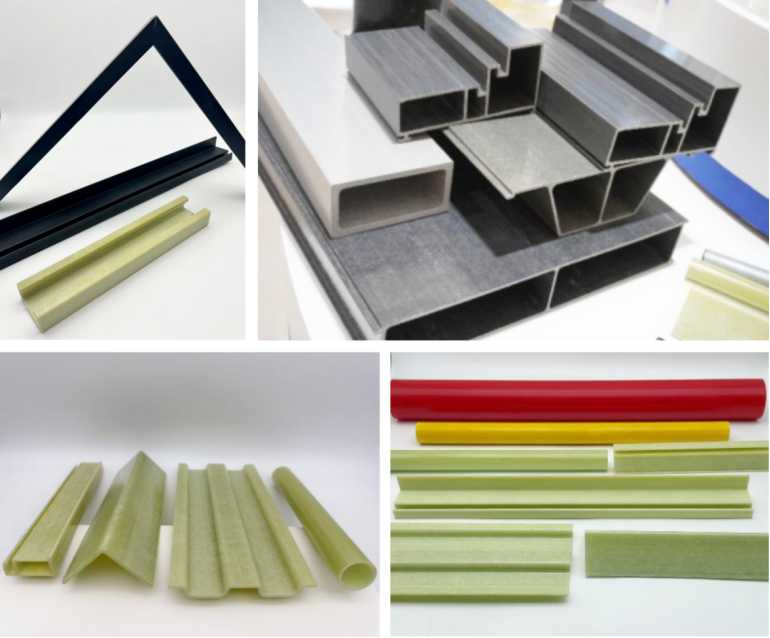

Samples of various polyurethane fiber composite materials

The material offers outstanding performance advantages:

Lightweight and high strength: can replace traditional materials such as steel, aluminum alloys, and PVC;

Excellent wear resistance: wear resistance is 2–7 times that of ordinary rubber;

High temperature resistance: can withstand environments as high as 130 °C for long periods;

Ultra-low thermal conductivity: thermal conductivity as low as 0.025 W/m·K, with excellent thermal insulation performance;

Green and environmentally friendly: solvent-free or waterborne system, VOC emissions can be reduced to zero, and the material is recyclable;

Easy to design and process: a wide adjustable performance range, adaptable to different requirements in construction, industry, agriculture, automobiles, energy, power generation, and aerospace.

Key technical points in production

In its R&D and production, Xiangyuan Chemical has summarized four core technical points to ensure stable material performance and product consistency:

Mold design and temperature control

Refined molds are used to ensure fine mold structure, and production temperature is precisely controlled to achieve uniform curing and dense forming of the reaction system. This ensures dimensional accuracy for all profile products and improves their mechanical properties.

Raw material selection and structural matching

According to product structure (specifications, cross-section, yarn wall thickness, etc.) and performance requirements (strength, toughness, elastic modulus, insulation, flame retardancy, weather resistance, etc.), appropriate systems of isocyanates, polyols, chain extenders, and related additives are accurately selected. The proportions of each raw material are precisely matched to ensure reliability of the material in different application scenarios.

Optimization of resin injection box and traction system

By improving the design of the resin injection box and optimizing the selection of traction clamps and equipment, uniform fiber impregnation and high-precision control of continuous pultrusion forming are achieved.

Standardized fabrication and optimization of technical formulations

Through continuous process optimization and data accumulation, a highly standardized and replicable production process has been formed. This ensures consistency of product performance between batches and guarantees the feasibility of industrial-scale mass production.

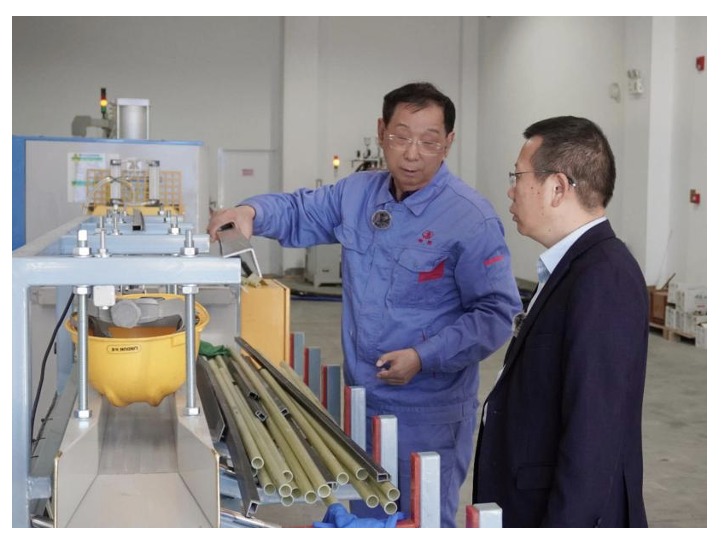

Experimental devices and on-site production photos

Industry significance and future development

Industry experts generally believe that polyurethane fiber composite materials are the best choice to replace traditional metal materials. They combine the advantages of light weight, high strength, wear resistance, corrosion resistance, weather resistance, durability, and designability, and represent an inevitable trend in the development of future materials technology. Xiangyuan Chemical’s technological breakthrough will significantly promote vehicle lightweighting, upgrading of agricultural equipment, innovation in wind power and photovoltaic structures, renovation of power and railway facilities, and the development of materials for the military and aerospace sectors, providing strong support for the high-quality development of China’s materials industry.

Chairman Zhou Jian (first from the left) introduces the production process to PUdaily

Although Chairman Zhou of Xiangyuan Chemical is already 76 years old, he still works on the front line of scientific research. He told PUdaily: “The R&D of high-performance polyurethane composite materials not only depends on innovation in raw materials and upgrading of technical formulations, but also requires close cooperation among equipment manufacturers, process engineers, and downstream application enterprises. Only when the upstream and downstream of the industrial chain work hand in hand can we promote high-quality development in this field.”

Led by Mr. Zhou, the team devoted themselves to research for one and a half years, and ultimately achieved key breakthroughs in production processes, material systems, and performance control. He stated that he is willing to share technology with peers in the industry, jointly promote the industrialization of high-performance polyurethane composite materials, and contribute to the development of China’s new materials industry.

Aerial view of Xiangyuan’s Nantong plant

About Xiangyuan Chemical: Leading technical strength and industry position

Founded in 2007, Xiangyuan Chemical is a wholly owned subsidiary of Suzhou Xiangyuan New Materials Co., Ltd., both established by Mr. Zhou Jian. It is an important modern, intelligent production base for polyurethane chain extenders and is currently the world’s largest and most technologically advanced MOCA production base.

In 2025, the company achieved a total annual production capacity of 35,000 tons of polyurethane chain extenders. Its products span more than 30 varieties of polyurethane chain extenders in five major series, including aromatic diamines, polyether amines, aliphatic diamines, and latent curing agents, and are supplied to more than 50 countries around the world.

Xiangyuan Chemical is a national “single champion” manufacturing enterprise, a nationally supported “specialized, sophisticated, distinctive, and innovative” little giant enterprise, and a national high-tech enterprise. It is also a leading enterprise for green development in Jiangsu Province. Years of accumulated technological advantages and rich production experience have laid a solid foundation for the company’s R&D in high-performance polyurethane composite materials, and it is committed to contributing to the high-quality development of China’s national industry.

PUdaily editor’s note:

Xiangyuan Chemical’s breakthrough in high-performance polyurethane fiber composite materials not only reflects the company’s technical strength, but also represents the innovative level of China’s materials industry. As demand for lightweight, green, and high-performance materials continues to grow, Xiangyuan Chemical’s innovative achievements will provide important support for industrial upgrading and sustainable development.

Source: PUdaily's News Center

We Make Your Market Decisions Smarter